|

|

Understanding Manufacturers' Claims - #2: Racket String Design

By Steve Crandall

Vice President, Sales & Marketing

Ashaway Racket Strings

|

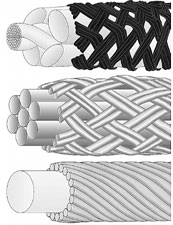

Strings differ in construction.

TOP: DuraKill™ string, with Kevlar® multifilament inner core and flattened semi-monofilament outer core.

MIDDLE: PowerKill™ Pro string, with Zyex®

"Semi-monofilament" core.

BOTTOM: multistranded monofilament design |

As we saw a couple issues ago, racquet strings are made from different fibers to accommodate the differing needs of "power" and "control" players. How those materials are put together-in other words, the string's design-also affects its performance. There are hundreds of string models available, with dozens of different design features. Here's how to make sense out of a fairly confusing selection of products.

Racquet strings have two basic components: a core and a jacket. The core is the central load-bearing member. It provides strength, and determines the majority of the string's "response"

characteristics: how much it will stretch when strung in the racquet; how much more it stretches when hitting the ball; and how quickly it rebounds.

Three basic core types exist. The monofilament core, found in string commonly called "tournament nylon", is the most common. It consists of a single thick nylon fiber, or a few medium-gauge nylon fibers that have been chemically bonded together so they are, in effect, a single thick filament.

Multifilament cores are made from thousands of very thin fibers twisted and/or braided together, but not chemically bonded: they're free to stretch somewhat independently from one another. As a result, multifilament cores are less stiff, or more resilient, than monofilament cores of the same material. And resiliency, as we know, generates more power, but at the expense of ball control. Multifilament cores may be made from nylon, polyester, Kevlar®, or other materials.

The third type is the composite, or "semi-monofilament" core, in which a small number of relatively thick fibers-usually between three and ten-are twisted or braided together, but not chemically bonded to each other. For example, the core of the PowerKill™ Pro racquetball string consists of five Zyex® monofilaments twisted around a sixth central one.

Manufacturers can make subtle adjustments in stiffness and responsiveness by combining different materials in a variety of configurations in composite-cored strings. The DuraKill™ string, for example, has a round inner core, composed of Kevlar multifilaments, surrounded by four "flattened" nylon monofilaments. This gives the string a somewhat squarish cross-section, which provides more "bite" on the ball.

During a match, the main strings in the racquet move back and forth against the cross strings, and would quickly be sawn through if it weren't for the string's abrasion-resistant jacket, also known as the cover or wear layer. The jacket also provides texture to the surface of the string, which is even more important than cross-sectional shape for "bite" or control. In multifilament and composite strings, the jacket also holds the core filaments together.

Jackets may be either twisted or braided over the core. Twisting provides a somewhat smoother surface, making it easier to string the racquet. Braiding produces a more textured surface, for more bite.

When a fiber breaks in a twisted jacket, it begins to unravel, and the string may deteriorate quickly with further use. In a braided cover, the over-under-over design locks all the fibers together, so the breakage of a single fiber doesn't mean the imminent death of the string. In fact, many jacket fibers may break and the string will remain intact. The broken jacket fibers will stick out, producing a somewhat "hairy" surface that aids ball control. Eventually, of course, even braided jackets become so worn they can no longer protect the core.

From three types of cores and two types of jackets, there are six basic combinations of string construction. Beyond that, hundreds of other possibilities exist: core fibers may be twisted or braided, and may have different numbers and types of fibers; jackets may be twisted or braided tighter or looser, and may consist of either one or two layers of different materials. The strands in each braid may be a single fiber, or may be a small bundle of two or three fibers.

Players need not, however, concern themselves with this level of detail. The sensible approach is to identify the basic core and jacket designs that are appropriate to your style of play, also bearing in mind the importance of different materials. Then, through play-testing, you can compare the string models that have the basic core/jacket combination you want, to find the one that feels right for you.

This article previously appeared in Racquetball Magazine.

|