|

|

Understanding String Construction

By Steve Crandall

Vice President, Sales & Marketing

Ashaway Racket Strings

In our past columns we have explored how any squash racquet can be "tuned" to provide more power, more control, greater durability, or better feel by selecting a string designed to optimize one or more of these qualities. Now we will take a deeper look at string construction because, as we've learned, the more you understand what goes into strings, the more you'll get out of your racquet.

In our past columns we have explored how any squash racquet can be "tuned" to provide more power, more control, greater durability, or better feel by selecting a string designed to optimize one or more of these qualities. Now we will take a deeper look at string construction because, as we've learned, the more you understand what goes into strings, the more you'll get out of your racquet.

There are two major components to squash strings. The core is the central load-bearing member. This provides strength, determines the string's stiffness or resiliency, and is the source of the racquet's power. The jacket or wear layer protects the core from abrasion and adds texture to the surface, which aids in ball control.

There are two types of core construction-monofilament and multifilament. A monofilament core is a single, heavy nylon fiber, similar to monofilament fishing line. Monofilament strings are durable but quite stiff, and for this reason they have fallen out of favor among squash players. They are, however, the most economical strings, and represent a viable choice for recreational players who have to watch their budget.

Multifilament cores are made from thousands of very thin fibers twisted together, which produces a soft, resilient feel and better dynamic elasticity. This means that at relatively high tension, where control is maximized, they still generate good power. So even though they're more expensive and not quite as durable as monofilament strings, multifilament strings are worth it for any squash player who takes the game seriously.

Most cores are made of nylon, but some manufacturers offer different materials that emphasize other performance characteristics. For example, the Zyex® fiber core of Ashaway's PowerNick™ string is made from a chemical called polyetheretherketone; this is stiffer than nylon multifilaments, but generates much more power than monofilaments and has tremendous tension-holding properties. It's a good choice for chronic string breakers and players who need more power in their game.

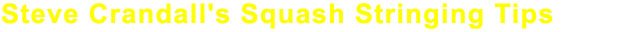

The jackets of almost all squash strings are also made of nylon, which is either braided or twisted over the core. Twisting creates a smooth surface, making it easier to string the racquet. Braiding produces a more textured surface, enhancing ball control. While both types of jackets protect the core, braiding is the more durable design. When a fiber in a twisted jacket breaks, it can unravel, exposing the core to damage. In contrast, the over-under-over arrangement of a braid locks the fibers together, so that when one breaks, it won't unravel so readily.

Some strings have two jackets, one braided right over the other. Obviously, this provides greater durability. It can also further enhance ball control, if the outermost layer is an "open" braid, with spaces between the fibers to produce more "bite" on the ball, as in Ashaway's SuperNick® XL string. The inner jacket layer is always a "closed" braid with the fibers densely spaced, for protection of the core.

Pay attention to the technical detail some manufacturers include on their packaging or in their ads. You can use this information to find the strings that are likely to have the performance characteristics you're looking for. Identify the strings that have the core-and-jacket combination you are looking for, then compare several models by play-testing until you find the one that feels right to you.

This article previously appeared in Squash Magazine.

|